Cleaner, Stronger Future!

Cerecrete is a team player, not a replacement.

Cercrete is not intended to replace or eliminate ordinary cement. Instead, it is used selectively in applications where it offers extraordinary advantages of which there are many. The product has been proven to be a superior alternative, a sustainable repair solution, or an enhancement of existing cement and concrete, particularly in infrastructure, commercial buildings, and housing. In some cases, it can significantly strengthen and improve the durability of existing structures with minimal application, even when applied as a thin, high-performance coating.

Cercrete can safely encase nuclear waste sites. Roughly 400 of these sites exist across the U.S. and globally. It provides superior protection against radiation exposure, addressing the risks posed by inferior ordinary concrete used as an encasement material. Additionally, it serves as a safeguard against toxic chemicals and other hazardous contaminants.

Cerecrete only one of very few domestic and global companies with the expertise and capability to manufacture and distribute ceramic cement products at scale—backed by proven validation. Our customers and clients will include construction and engineering firms, cement companies, traditional and modular home builders, municipal and state governments, federal agencies (DOE, highway and runway projects), the oil and gas industry, and international purchasers

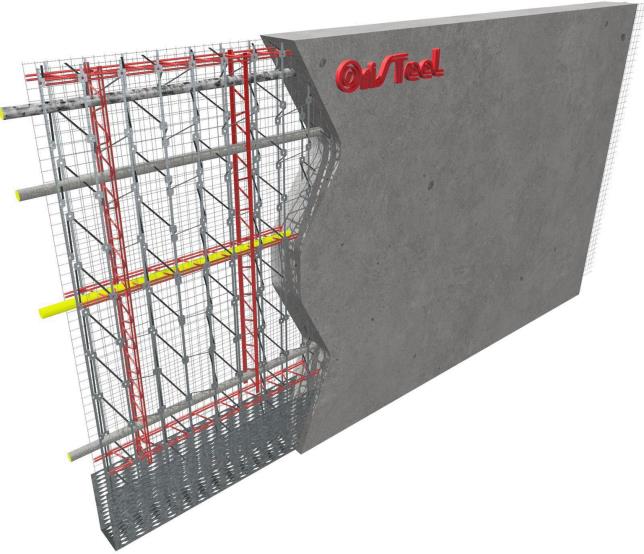

CGS will also help make homeownership more attainable by supplying Cercrete directly to modular home builders as part of our uniquely designed panel and wall system. This system integrates Cercrete into the panels, forming both the inner and outer faces, which are securely connected within the structure. As a result, these homes offer superior strength, fire resistance, and sustainability compared to traditional models. Under Jeff’s direction and supervision, numerous modular homes were previously built using a precast product he designed and developed; this product closely resembled Cercrete.